Nickel Centrifugal Pump for Caustic Soda

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Guangxi,Chengdu |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Guangxi,Chengdu |

Model No.: HZ80-50-200

Brand: GAOFENG

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden case or Frame steel Case |

The file is encrypted. Please fill in the following information to continue accessing it

Nickel Pump for Caustic Soda Factory

Since 1980, the company has specialized in the development of single-stage centrifugal pumps, and is committed to promoting the advancement of centrifugal pumps. We have delivered more than 500,000 units to our customers, all of which exceed the standards and customer requirements.

The HZ series processes include HZ and HZJ models, and their design standards are based on ISO5199 and ISO2858. After long-term research and development investment and technological innovation, excellent performance and reliability are guaranteed.

Anti-corrosion pump For Alkali Plant/Anti-rust pump for Soda Plant/Wear-resistant Chemical pump Application condition

The HZ pump is designed to cover a wide range of hydraulic performance applications and to meet the challenges of complex fluid media

■Salt industry

■Alkali industry

■Glauber industry

■Sewage treatment

■Paper industry

Hydraulic range

| Medium | Hydraulic parameter range |

| Clean liquid | Flow:2~2050 m3/h |

| Corrosive liquid | Head:3~150 m |

| High temperature liquid | Pressure:0-1.6 MPa |

| Fiber slurry | Temperature:-20~150℃ |

| Viscous liquid | Density:≤1850 kg/m3 |

| Containing a large amount of granular slurry | Viscosity:≤300㎜2/s |

① Shaft seal environment

A variety of sealing forms that match interchangeability for different operating conditions;

Cartridge structure, easy to install and replace, no need to measure;

The large conical seal chamber improves the lubrication of the seal and fully achieves "self-lubrication".

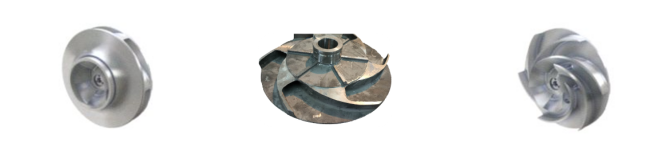

② Impeller

Designed in accordance with ISO5199 standard, the mechanical seal has the longest life;

A variety of impeller structure design, using different working conditions

Standard back blade or balance hole reduces axial thrust and seal chamber pressure for extended bearing and seal life

③ Bearing housing

Large cavity reduces oil temperature and extends bearing life;

Strong support for shafts and bearings with high reliability;

The use of a magnetic oil plug reduces the fouling of the lubricating oil;

Specially designed contactless oil seal structure;

④ Pump body

Heavy duty top centerline outlet pump casing;

Rear door structure design, easy to install and maintain;

Replaceable pump body seal ring keeps the pump running efficiently;

⑤ Bearing system

Equipped with heavy-duty bearings to minimize the cost of accidental downtime to customers;

Reasonable bearing pairing, so that the L10h bearing life exceeds 25,000 hours;

ISO-compliant stainless steel shafts provide reliable power transmission and corrosion resistance to the rotor components of the pump;

Configuration:

Common material configuration table

| Type | China | USA | Japan | ||||

| GB/T 1220 GB/ 20878 (sectional material) | GB/T 2100(casting) | UNS | AISI/ ASTM | ACI (casting) | Code | ||

| Grade | Code | ||||||

| Austenitic stainless steel | 1Cr17Ni7 |

|

| S30100 | 301 |

| SUS301 |

| 0Cr19Ni9 | ZG0Cr18Ni9 | 302 | S30400 | 304 | CF-8 | SUS304 | |

| 00Cr19Ni11 | ZG00Cr18Ni10 | 301 | S30403 | 304L | CF-3 | SUS304L | |

| 0Cr17Ni12Mo2 |

|

| S31600 | 316 | CF-8M | SUS316 | |

| 00Cr17Ni14Mo2 |

|

| S31603 | 316L | CF-3M | SUS316L | |

| 0Cr18Ni11Ti |

|

| S32100 | 321 |

| SUS321 | |

|

| 00Cr20Ni25Mo4Cu |

| N08904 | 904L | |||

| Two-way stainless steel |

| 00Cr22Ni5Mo3N |

| S31803 | 2205 | ||

|

| 00Cr25Ni7Mo4N |

| S32750 | 2507TM | |||

|

| 0Cr26Ni5Mo2Cu3 |

|

| CD4MCu | |||

|

Martensitic stainless steel | 0Cr13 |

|

| S41000 | 410S |

| SUS410S |

| 1Cr13 | ZG1Cr13 | 101 | S41000 | 410 | CA-15 | SUS410 | |

| 2Cr13 | ZG2Cr13 | 102 | S42000 | 420 | CA-40 | SUS410J1 | |

| 3Cr13 |

|

|

|

|

| SUS410J2 | |

| 1Cr13Mo |

|

|

|

| CA-15M |

| |

| 1Cr17Ni2 |

|

| S43100 | 431 | CB-30 | SUS431 | |

| Precipitation hardening | 0Cr17Ni4Cu4Nb | ZG0Cr17Ni4Cu4Nb | 501 |

| 17-4PH | CB-7Cu |

|

| 0Cr17Ni7AL |

|

| S17700 | 631 |

| SUS631 | |

| 0Cr15Ni7Mo2AL |

|

|

|

|

|

| |

| Titanium and titanium alloy | TA2 |

|

|

|

|

| |

| TA10 |

|

|

|

|

| ||

| TA9 |

|

|

|

|

| ||

| TA9-1 |

|

|

|

| | ||

Note: The above table is a list of commonly used materials. If the required materials are not listed in the above table, please contact us.

HZ Product Structure

Closed impeller Semi-open impeller Open impeller

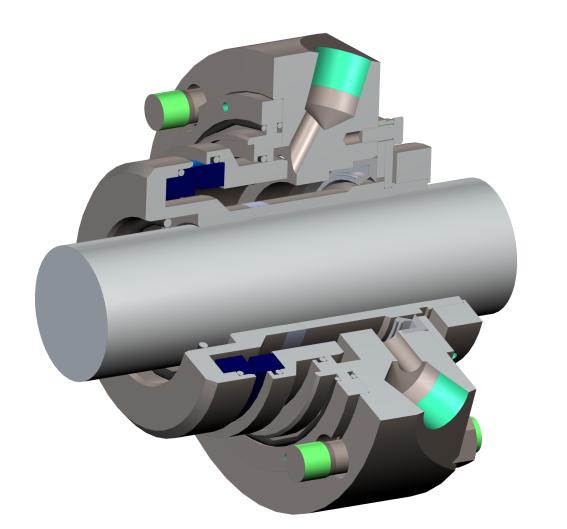

Shaft seal system

Choose reliable shaft seals for pumping liquids and operating conditions, reducing operating costs and minimizing downtime

Single mechanical seal

The shaft seal is designed in accordance with the API682 standard.

Usually adopt Plan02/Plan32 or Plan62 flushing scheme

According to different working conditions, choose the flushing water pressure

The flow rate is usually 3-5L/min

Double mechanical seal

Double mechanical seal

The shaft seal is designed according to API682 standard,

usually adopting Plan54 flushing scheme

The flushing water pressure is 0.5 bar higher

than the seal chamber pressure

The flow rate is usually 3-5L/min

Packing and Delivery

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.